Air Roasted Coffee

At Canopy Point, we provide a unique and innovative roasting method, called “fluidized bed roasting” or “air roasting.” Our roasters use hot air to gently agitate the coffee beans and bring them to the precise degree of roast. Since they use electricity as a heat source, the roasted coffee flavors are not affected by the burnt and over-roasted flavors that are associated with traditional gas-fired roasters. This allows the subtle, sweet flavors of the coffees to naturally shine through while using a renewable energy source rather than fossil fuels.

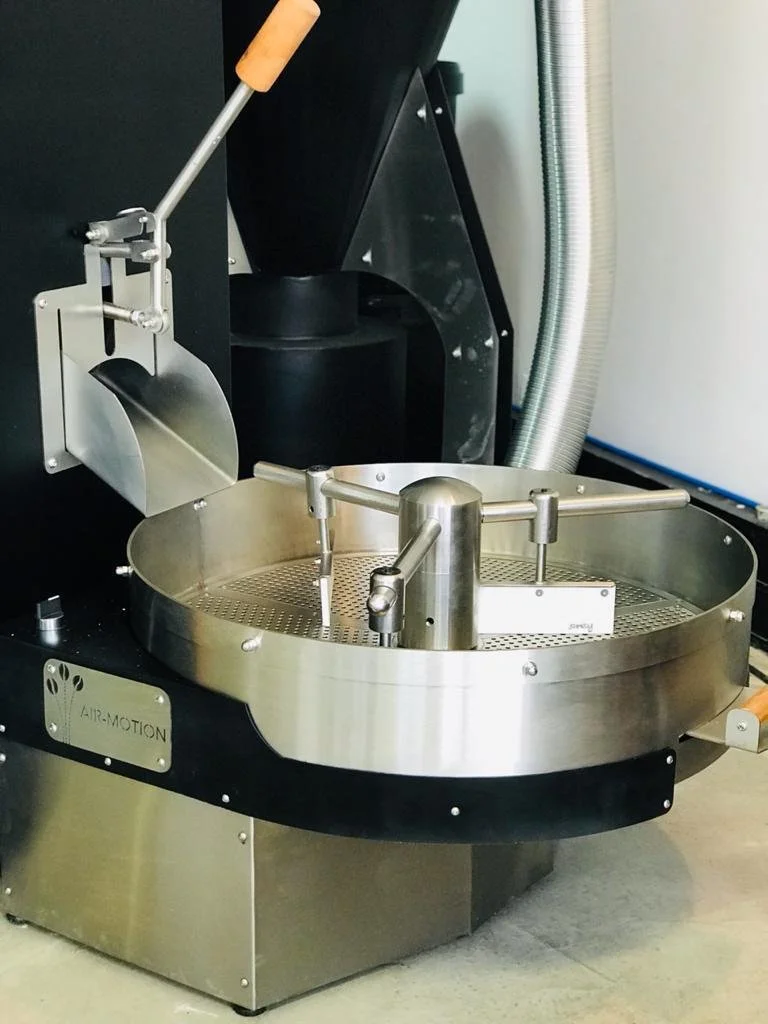

Canopy Point has partnered with Air-Motion Roasters to roast our coffees in-house. The Air-Roasting process involves coffee beans being suspended and roasted on a bed of hot air. The vortex within the roasting chamber created by the air roasts each coffee bean at the same rate from all directions. The Air-Roaster also removes dust, chaff, and smoke from the roast chamber, ensuring a clean, pure, and balanced roast. With Air-Roasted Coffee, you taste the coffee, not the roaster.

About Our

Roaster

-

Air-Motion Roasters have used cutting edge expertise to manufacture the Air-Roasting technology. 21st century modern design, an instant startup, immediate heat response and basically as simple as ‘plug and play’. No delays and no energy wastage!

-

The design of the Air-Motion Roaster provides the roaster with full control and interaction with the beans throughout the roast offering an intimate experience between the artist and his beans, in the creation of his masterpiece.

-

Seamless and intuitive software enables roasters to work with ease and achieve their desired roast in a matter of minutes". Bruce Manning / Brustar Specialty Coffee: "I was humbled to learn that this simple technology could, in fact, perform as well as, and even better in many respects, than any traditional ‘cast-iron rich’ drum roaster.

-

The Air-Motion Roast Chamber has a 3kg, 6kg or a 12kg roast capacity, driven by an immediate heat response electrical element bank

-

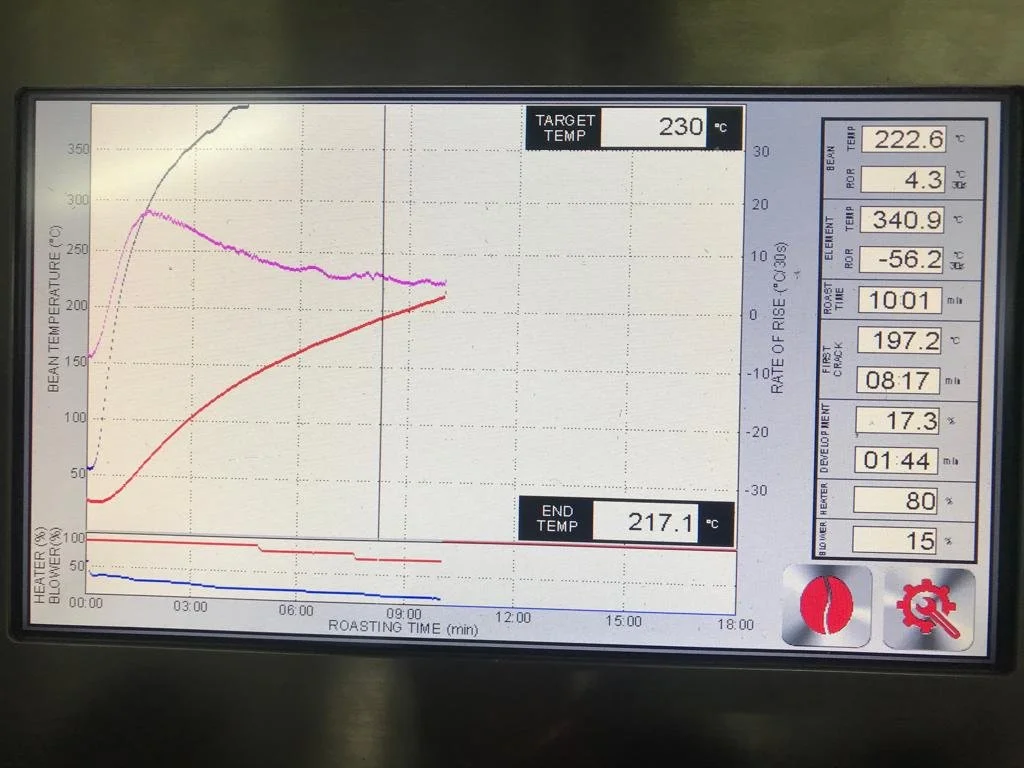

Touchscreen interface control panel tracking the roast profile with real-time feedback and graphs.

-

The cyclone removes dust, chaff and smoke from the roast chamber, it also provides a water dousing system to immediately stop the roast when target temperatures are reached.

Learn More